Metal Powder Works Limited Doubles Production Capacity by 100+ Tons, Boosts Efficiency by 40%, and Eyes Expanding USA Defence and Marine Markets

Monday, June 2, 2025

at

8:55 am

Metal Powder Works Limited has doubled its DirectPowder™ production capacity without extra capital expenditure. Improved tooling and process optimization now deliver a 40% faster cycle and less waste, positioning the company to meet growing demand in advanced metal powders for US defence and industrial applications.

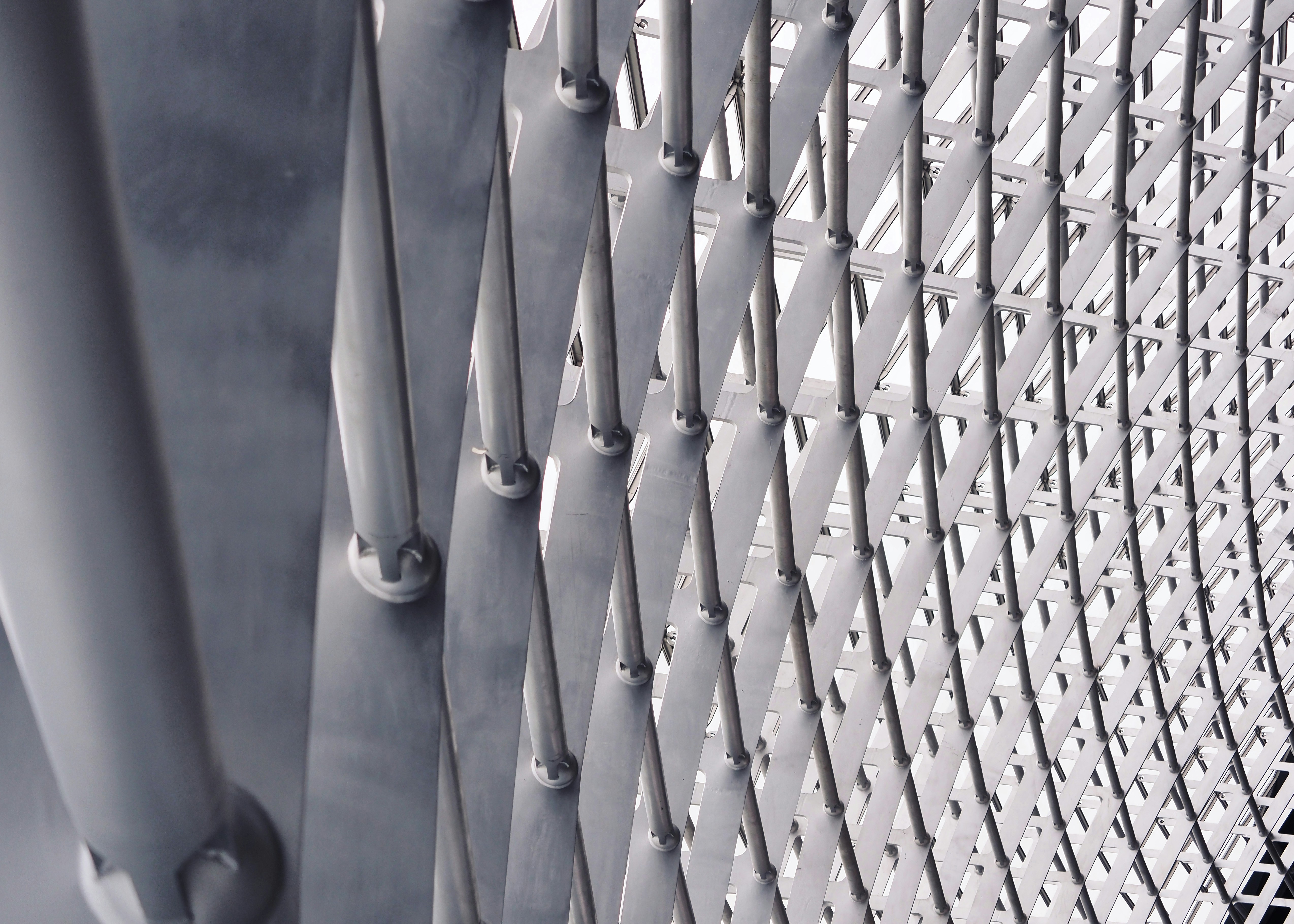

Metal Powder Works Limited has announced a significant technological advancement by doubling the production capacity of its patented DirectPowder™ process. The company achieved this milestone without incurring additional capital expenditure, thanks to improvements in tooling and process optimization. Alongside the capacity boost, the engineering team has enhanced material utilization, reducing waste and shortening the production cycle by up to 40%. These improvements enable the company to now produce over 100 metric tons of high-quality metal powders, including copper, nickel aluminum bronze, and copper nickel bronze alloys.

These advancements come at a time when the demand for advanced metal powders is growing rapidly. With plans to establish a production presence supporting the US Defence Industrial Base, Metal Powder Works has already provided trial quantities of copper nickel bronze, a material highly sought after for its corrosion resistance and strength in naval applications. Industry reports indicate that the North American market for copper-nickel alloys is set to expand from around US$594 million in 2022 to over US$802 million by 2028. In the global arena, the metal powder market is expected to grow at a compound annual rate of 5.8% from 2024, driven by rising demand in aerospace, defence, and additive manufacturing sectors.

The firm’s Managing Director highlighted that the successful implementation of these milestones was delivered on time and within budget, underscoring the company’s commitment to scaling operations efficiently without the heavy costs typically associated with new capital investments. This accomplishment positions Metal Powder Works Limited as a potential key supplier in emerging high-growth markets, leveraging its proprietary process to convert premium bar stock into a range of advanced metal powders.

Investors may view these developments with optimism due to the operational efficiency gains and expanded production capacity, which could translate into stronger market penetration and revenue growth in an industry marked by robust demand. On the other hand, skeptics might point to the inherent risks of scaling new technologies and market uncertainties, which remain common challenges for companies operating in highly technical manufacturing environments. Ultimately, while the technical enhancements and market opportunities signal a bullish outlook, cautious investors will likely monitor the company’s ability to maintain momentum amid a competitive landscape.